What is the product being soldered?

What soldering material is used? Solder wire (what diameter?), solder paste, or solder bar?

What level of positioning accuracy needs to be achieved?

What other configurations are required?

4 Axis Robotic Vision Soldering Machine

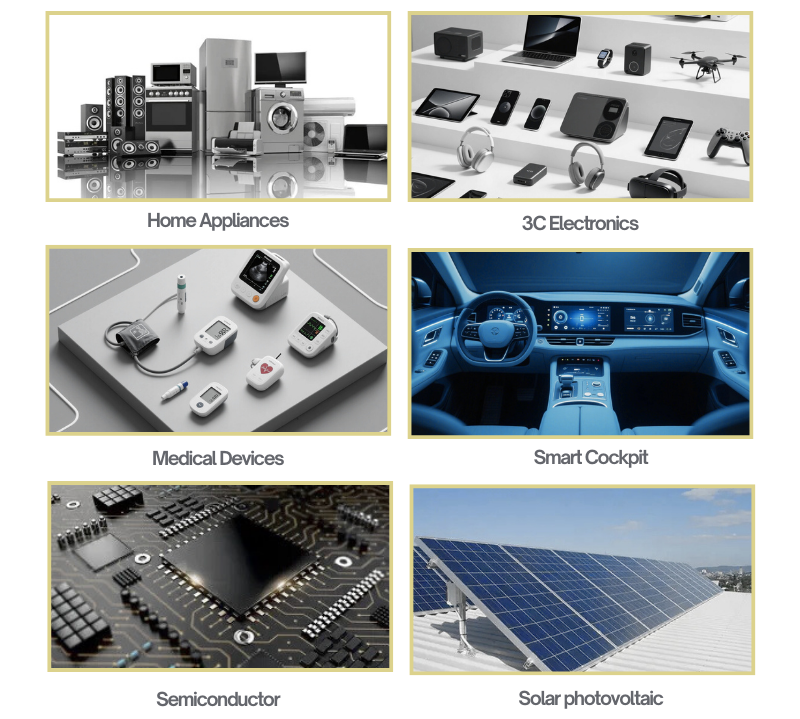

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment. Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

Please let us know !

| Robot Travel Range | 600*(R)360° |

| Robot Speed | 1600mm/s |

| Program Recording Mode | 99groups |

| Repeatability Accuracy | ±0.03 mm |

| Control System | Motion control card+PC+PLC |

| Photoelectric Sensor | Taiwan brand |

| I/O Signal | 12 Inputs/12 Outputs |

| Display Method | Display+Touch screen |

| Motion Graphics | Spot soldering/Drag soldering/Arc drag soldering |

| Cleaning | Automatic |

| Power Supply | AC220V/50HZ |

| Belt Conveyor | Belt width(100MM) |

| Dimensions | L1200mm*W1000mm*H1850mm |

1. The robot serves as the execution mechanism of the equipment, responsible for precise positioning and performing soldering operations during the soldering process.

2. The PLC acts as the core control system of the equipment, receiving data from the vision recognition system and issuing commands to the robot, enabling automated and intelligent management of the entire soldering process.

3. The vision recognition system employs advanced image processing and machine vision technologies to accurately identify and position workpieces, ensuring the precision of soldering locations.

4. The dual-belt conveyor functions as the feeding mechanism. Its dual-belt design ensures stable and continuous transportation of workpieces to be soldered to designated positions, providing the robot with a steady supply of materials for processing.

5. The soldering system includes components such as the soldering gun and solder wire, which carry out soldering operations based on PLC commands to complete workpiece welding.

6. Other auxiliary equipment, such as blocking mechanisms, cleaning devices, and safety protection devices, are used to enhance the stability and safety of the equipment.

In-line robotic vision soldering machines are widely used in electronics, automotive, home appliances, power strips, and communication industries. They are particularly suitable for production scenarios requiring high soldering precision and efficiency, such as soldering operations for precision electronic components including mobile phone mainboards, computer motherboards, and automotive electronic control units (ECUs).

Please let us know !

What is the product being soldered?

What soldering material is used? Solder wire (what diameter?), solder paste, or solder bar?

What level of positioning accuracy needs to be achieved?

What other configurations are required?