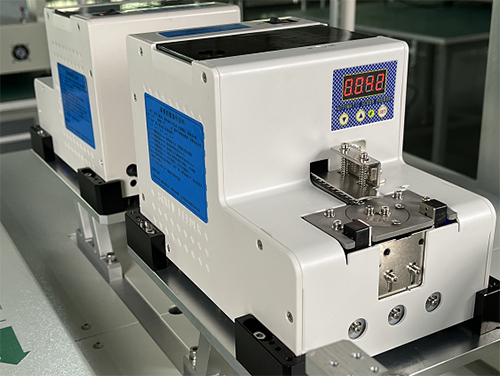

Back to Back Screw Tightening Machine

Device Parameter

| Model | GR-XF668811 |

| Y-axis load | 10Kg |

| X*Y*Z | 500*300*300*100mm |

| Weight (KG) | 120kg |

| Size(L*W*H) | 116*82*78cm |

| Accreditation standards | CE |

| Stroke(X*y*Z) | 600,600,800,800,100,100 |

| Lock-up yield | 99.98% |

| Working power supply | 0.4-0.7MPa |

| Axis movement speed | 0-1200mm,s |

| Set the coordinate method | Touch screen+handheld programmer |

| Outer demension (L*W*H) | 116*82*78cm |

| Lock efficiency | A single screw is about 0.9-1.2S |

| Marketing Type | Hot Product 2024 |

| Warranty of core components | 2 Year |

| Brand Name | Green |

| Power | Approx 1KW |

| Standard Configuration | Specification |

| Driving mode | Synchronous belt + closed loop motor repetitive precision soil 0.05mme |

| Feeder | Adsorption feeder |

| Electrical batch | Servo electric batch |

| Drive mode | Screw+servo motor Repeatability±0.02mm |

| Feeder | Vibrating plate+material distribution mechanism |

| Electric batch | Smart electric batch |

Device features

1.Support alarm detection such as leaky lock,tooth slipping,floating and so on.The software comes with a floating height repair function;

2.The system is equipped with Panasonic PLC and 7-inch touch screen;

3.999 groups of different formulas can be edited at the same time,and up to 500 screws can be locked for a single product;

4.Compatible with M2-M6 size screws;

5.Z-axis can be equipped with laser displacement sensor (float height measurement),downforce detection sensor (optional);

6.The electric batch can be equipped with HIOS electric batch,Qili speed electric batch,servo electric batch, intelligent electric batch,etc.(optional);

7.The equipment can upload MES according to customer needs,such as torque,number of turns,angle,torque curve diagram,lock status (optional);

8.Manual code scanning and automatic code scanning can be selected (optional)

9.The production data can be traced,and the software comes with a quality control kanban.All kinds of data can be uploaded and downloaded (optional).

Application range

Mobile phones,automotive electronics,tablets,wireless charging,electronic cigarettes,watches, smart wear,remote controls,cameras,routers,set-top boxes,game controllers,POS machines,etc

Details