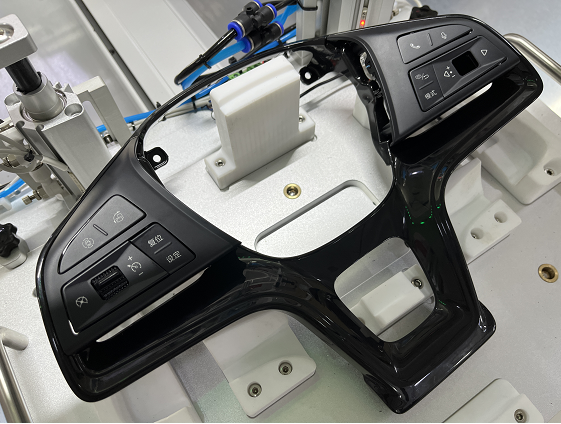

Four-axis Robot Adsorption Type Screw Tightening Machine

Device Parameter

| item | Specifications |

| Model | GR-XFSZ600/GR-XFSZ800 |

| Robot reach | 600mm/800mm |

| Brand Name | GREEN |

| Keywords | machine screw |

| Feed shaft stroke | 500mm/800mm |

| Size(L*W*H) | 1300*1000*1950mm/1500*1200*1950mm |

| Program storage capacity | 0-1200 mm/s |

| Axis movement speed | 999 groups |

| Lock-up efficiency | single screw is about 2.0-2.5S |

| Lock-up yield | 99.98% |

| Working power supply | AC220V |

| Working air source | 0.4-0.7MPa |

| power | Approximately 1.5KW |

Device features

1.Stand-alone offline structure,the feeding platform moves to realize product feeding/discharging,and thefour-axis robot linkage realizes screw locking

2.IPC motion control system,visual programming,unlimited data saving;

3.Graphical display of locking points and locking results,automatic marking of OK/NG screw points,intuitive and fast search;

4.Multi-user,multi-level permission management,administrators can create new accounts and assign softwareoperation permissions

5.CCD-assisted teaching screw coordinate points to eliminate manual visual positioning errors;CCD visual positioning correction coordinate points,intelligent combination correction of multiple groups of Mark points, Improve the first-pass rate of photography;

6.Support alarm detection such as leaky lock,sliding teeth,float and so on.The software comes with a floating height repair function;

7.7.Z-axis can be equipped with laser displacement sensor (float height measurement),downforce detection sensor (optional);

8.The electric batch can be equipped with HIOS electric batch,Qili speed electric batch,servo electric batch,intelligent electric batch,etc.(optional);

9.The equipment can upload MES according to customer needs,such as torque,number of turns,angle,torque curve diagram,and lock status.

10.Manual code scanning and automatic code scanning can be selected (optional)

11.Production data can be traced,and the software comes with a quality control kanban.All kinds of data can be uploaded and downloaded (optional); 12.Automatic torque spot check,store the torque spot check results and can query (optional).

Details Show