Table Top Soldering Robot Machine Automatic Soldering Machine for PCBA

Device Parameter

| Item | Specification |

| Product name | Industrial automatic soldering robot |

| Model | SI500DR |

|

Working range |

SI500DR(500*300*300*100*360°);SI600DR(600*400*400*100*360°)SI300R(300*300*100*360°);SI400R(400*300*300*360°);SI500R(500*500*100*360°); |

| Z axis load | 4kg |

| XY max. speed | 500mm/s |

| Z axis max. speed | 250mm/s |

| Repeatability | ±0.02mm |

| Program capacity | 150 files(1500 solder joints/file) |

| Control method | 3-dimensional interpolation |

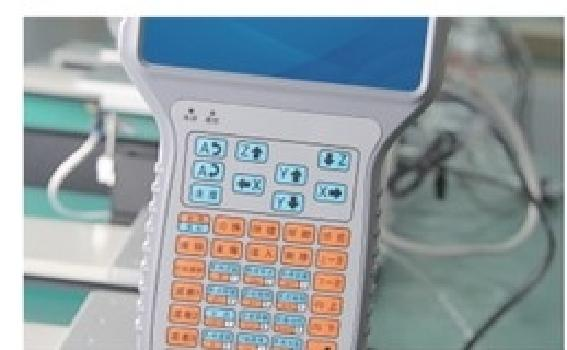

| Setting method | Handheld programmer |

| Temperature range | 0-450℃ |

| Alarm temperature range | ±10℃ |

| Heating time | 0-9.9s |

| Available tin wire diameter | φ0.5-φ1.5mm |

| Angle of soldering tip | 60°-90° |

| Temperature controller | 150W Green customized temperature controller(400W for optional) |

| Input voltage | AC 220V 10A 50-60HZ |

| Power(max.) | 800W |

| Drive method | Stepping motor+timing belt+precision guide rail;Servo motor+screw+precision guide rail (for optional) |

| keywords | automatic soldering machines |

Device features

1.Comprehensive 3D support, including 3D lines, 3D graphics teaching, 3D custom arrays and other functions.

2.Highly reliable metal anti-static mode design makes welding of sensitive components safer. The input setting parameters are safer, faster and more convenient. The machine is more flexible and lighter than manual.

3.Easy to operate, novice can save 50% of labor force after two hours of proficiency. Space saving, temperature, tin feeding speed, tin point size adjustable.

4.It is especially suitable for welding and docking of various electronic connectors, LED light strings, video and audio cable plugs, headphone cables, computer data cables, small circuit boards and small electronic components in the middle of the wire harness.

5.The automatic soldering machine mainly replaces the repetitive simple manual soldering action. The biggest advantage is good solder joint consistency and stable quality. For some products, the efficiency will be significantly improved.

6.It provides multiple processing modes such as single step operation, overall processing and automatic cycle processing. Customized array function, easy to deal with mold deviation.

7.Group function. You can quickly copy, delete, correct, array, and translate multiple points.

8.Unique file connection function. It can realize the interweave processing of complex multi-layer irregular array and non array graphics.

9.The discharge amount of isolated points can be controlled independently, and the parameters of any number of isolated points can be modified at one time.

Green Benchtop Soldering Machine SI500R

Widely used in series of products:

1.Optical products: cameras, cameras, mobile phones, etc.

2.Electronic products: mechanical parts, printing motherboards, small switches, capacitors, variable resistors, oscillators, LED, magnetic heads, relays, connectors, engines, transformers, SMD resistor components, chips, modules, etc.

3.General household appliances: DVD, audio equipment, car navigation system, TV, game machine, washing machine, refrigerator, vacuum cleaner, rice cooker, etc.

4.Electrical products: fans, VTRs, video recorders, mobile phones, PADs, printers, copiers, calculators, LCD TVs, medical devices, etc.

5. General consumer goods: typewriters, toys. Musical instrument, CD, battery, electronic clock, etc.

6. LSI/IC/hybrid IC,CSP ,BGA and other semiconductor welding;

Details Show

Application Range

Mobile phones,computers,integrated circuits,tablets,digital Automotive industry Battery assembly Speaker,PCB board Semiconductor microelectronics assembly Camera module solder.