In-line AI Version 3D AOI Machine Automated Optical Inspection System for PCB Pre-reflow and Post-reflow

Aviation, smartphones, automotive manufacturing, tablets, FPCs, digital appliances, displays, backlights, LEDs, medical devices, Mini LEDs, semiconductors, industrial controls, and other electronics fields.

| PCB Thickness Range | 0.4‒6mm |

| PCB Process Edge Width | 3mm |

| PCB Size Range | Single-track mode: Min 50×50mm / Max 500×460mm |

| Minimum Component Size Supported | 0201 |

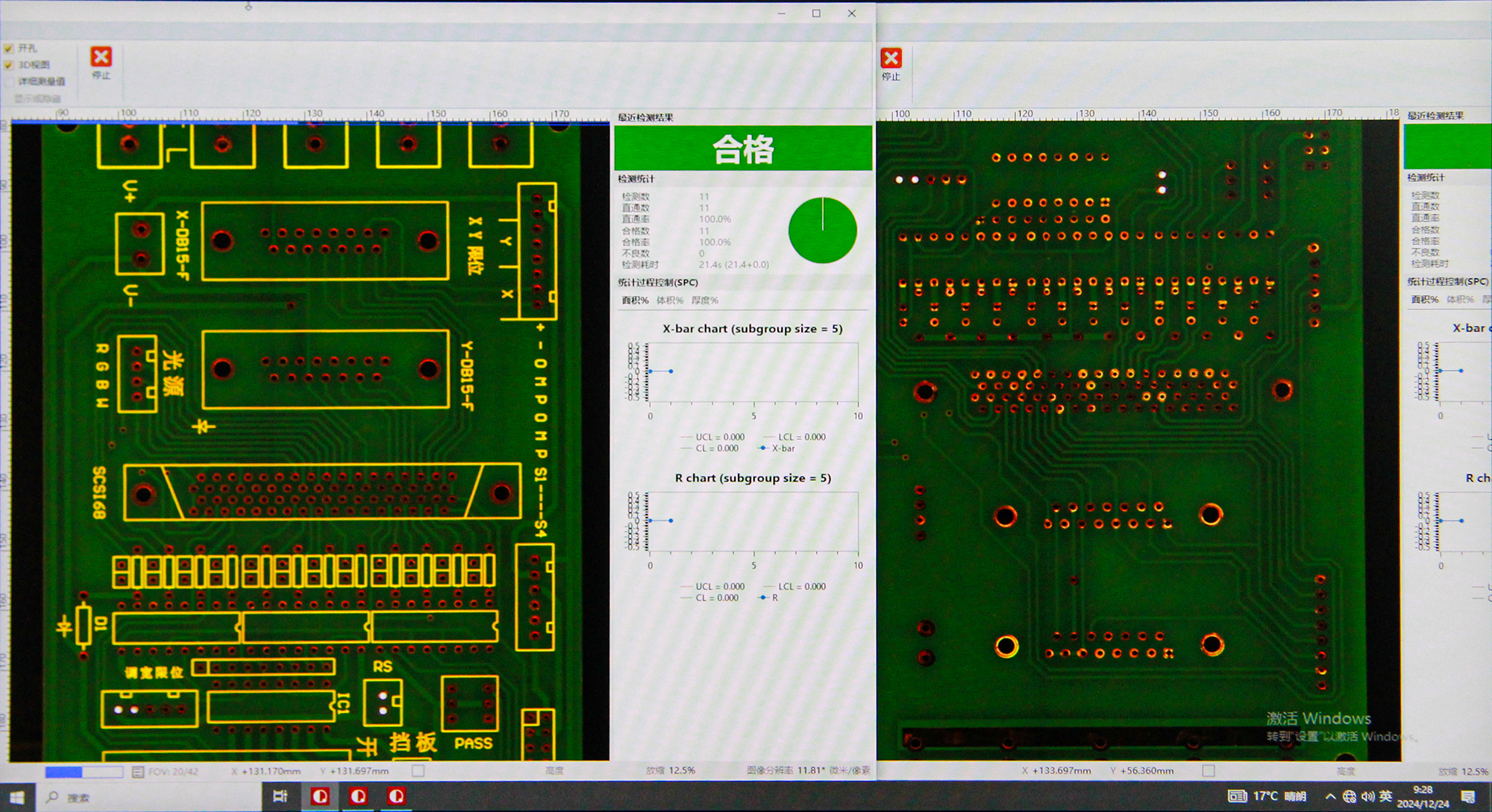

| Placement Defects | Missing components, misalignment, skewed, tombstoning, billboard, flipped components, polarity errors, wrong components, cracks, bridging, IC bent pins |

| Reflow Defects | Missing components, misalignment, tombstoning, flipped components, polarity errors, wrong components, cracks, bridging, high position, voids, IC warped pins |

| PCB Flatness | <5mm/1 (Fixtures assist in correcting deformation to eliminate PCB warping effects) |

| Camera Resolution | 12MP color high-speed industrial camera |

| Optical Resolution | 15μm |

| FOV Size | 60×45mm |

| Inspection Speed | 0.45 sec/FOV |

| Projector | 4-Pathway DLP projector |

| Barcode Recognition | Supports 1D/2D barcode smart recognition |

| SPC Data Analysis | Standard SPC module included |

| Barcode Scanning | Direct camera scanning / external barcode scanner |

| MES Function | MES data tracking |

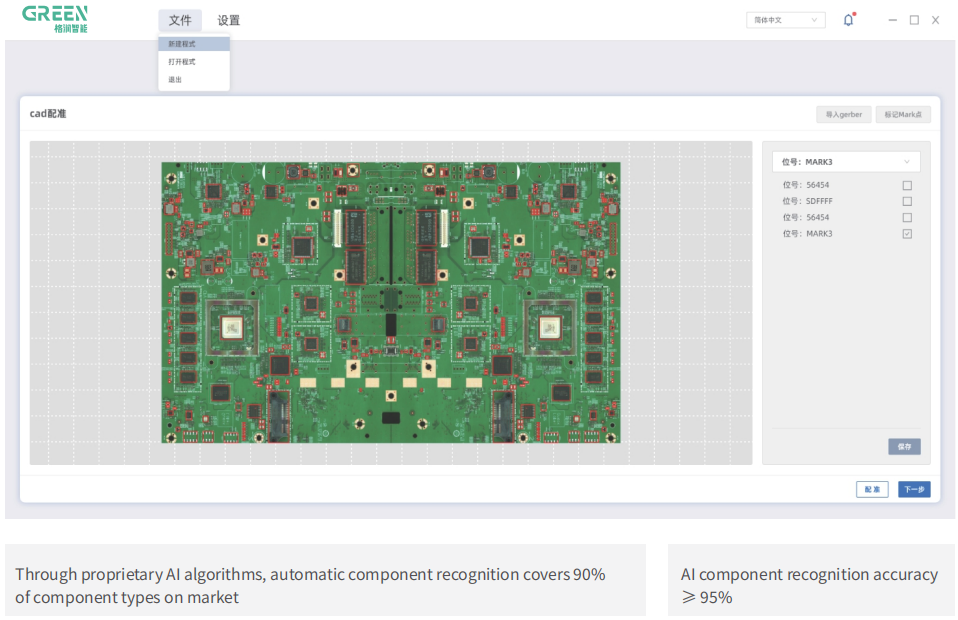

| AI Capability | AI big data training center |

| Drive Method | Servo motor |

| Track Mode | Single-track |

| Max Component Height Tolerance | ±35mm (upper)/25mm (lower) |

| Frame Structure | Lead screw and linear guides |

| Track Width Adjustment | Auto-width adjustment |

| Track Height | 900mm × 20mm |

| PCB Conveyance Direction | Standard: Left to Right |

| Computer | Industrial PC, 128GB RAM / 1TB HDD / Windows 10 64-bit |

| Power | AC 220V, 2KW |

| Working Air Pressure | 0.35‒0.55MPa |

| Weight & Size | 800kg, L1100mm × W1450mm × H1550mm |

Write your message here and send it to us