In-line AI Version Top and Bottom Lighting AOI Machine Automated Optical Inspection System for PCBA Wave Soldering

Aviation, smartphones, automotive manufacturing, tablets, FPCs, digital appliances, displays, backlights, LEDs, medical devices, Mini LEDs, semiconductors, industrial controls, and other electronics fields.

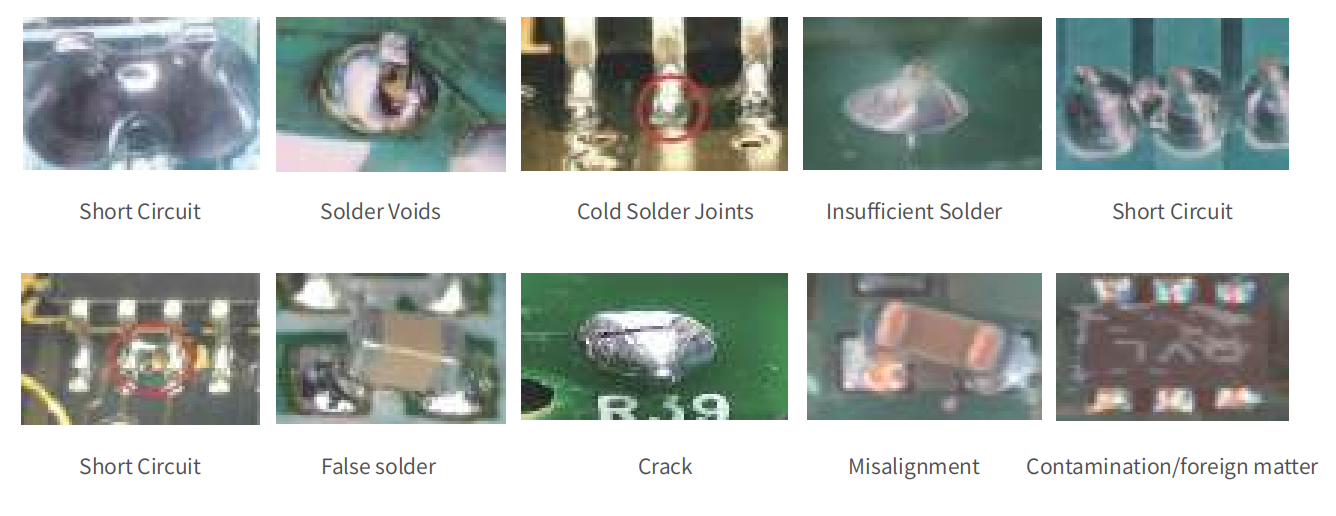

Inspection Defects

Post-wave soldering defects: contamination, solder bridging, insufficient/excess solder, missing leads, voids, solder balls, wrong missing components, etc.

| AI Intelligent Assisted Modeling: Rapid modeling without parameter setup. | ||

| Core Features: Deep learning algorithms, fast programming, high-precision model training, remote control. | ||

| One-Click Intelligent Search: Supports 80+ component types, compatible with morphological variations. Automatically identifies components and classifies defects. | ||

| Online First-Board Snapshot System for Automated Program Diagram Generation. | ||

| Powerful Learning Capability: Supports continuous incremental learning (improves with more training). | ||

| Advanced Character Recognition Functionality: Accurately identifies diverse characters with high efficiency. | ||

| Top imaging, bottom imaging, and dual imaging (top + bottom) are flexibly configurable to adapt to multiple scenarios. | ||

| Multi-task software architecture design and testing, synchronously support on-line editation in real time, with automatic synchronization upon saving. | ||

| SPC | Provides real-time statistical analysis data and diverse statistical charts | |

| Voice Broadcast | Supported | |

| Multi-Project Inspection | Co-line production for multiple types of machines (6 options available) | |

| Board Conveyance Direction | Dual-direction flow | |

| Multi-Project Inspection | Supported | |

| Inspection Items | Bottom imaging inspection (Soldering Defects): Short circuits, exposed copper, missing leads component absence, pinholes, insufficient solder, SMT component body, and soldering issues. | |

| Custom Voice Alerts | Supported | |

| Remote Control & Debugging | Supported | |

| Communication Interface | SMEM4 interface | |

|

Hardware Configuration |

Light Source | RGB or RGBW Integrated Ring Light |

| Lens | 15/20μm High-Precision Lens | |

| Camera | 12-Megapixel High-Speed Industrial Camera | |

| Computer | Intel i7 CPU / NVIDIA RTX 3060 GPU /64GB RAM / 1TB SSD / Windows10 | |

| Monitor | 22" FHD Display | |

| Dimension | L1100 × D1450 × H1500 mm | |

| Power Consumtion | AC 220V±10%, 50Hz | |

| Machine weight | 850KG | |

Write your message here and send it to us