What is the product being dispensed?

What type of adhesive is required?

What are the dispensing patterns and paths?

What are the accuracy requirements for dispensing?

Inline 6 Axis Robotic Liquid Glue Dispensing System GR-0D008-D12

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment. Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

Please let us know !

| Operating Mode | Inline type |

| Motion Type | 6-axis robot |

| Vision System | Industrial PC dispensing software |

| Programmable Motion Path | Point, line, arc, curve, polyline, spiral, ellipse |

| Conveyor Width Adjustment | Automatic width adjustment |

| Dispensing Range | 500×400mm |

| Operating Speed | 0~800mm/sec |

| Repeatability | ±0.02 mm |

| Load Capacity | Conveyor load 20KG, robot head load 5KG |

| Conveyor Type | 2.5x speed chain |

| Control System | PLC + touch screen + industrial PC |

| Carrier Transport Method | Left in right out/left in left out/right in right out/right in left out |

| Calibration System | Automatic needle alignment mechanism |

| Display Type | Touch screen + display |

| Carrier Positioning | Stopper + lifter + side-push mechanism |

| Conveyor Drive Method | Stepper motor |

| Input Air Supply | 4-6 bar,100 L/min |

| Power Input | AC220V/50HZ |

| Dimensions | L1350mm×W1200mm×H1950mm |

CCD Vision Positioning

XYZ-Axis Reference Calibration System

| Glue Path Visual Inspection | |

| 3D Scanning/Path Guidance | |

| Laser Height Measurement | |

| Automatic Nozzle Alignment | |

| Glue Shortage Alarm | |

| Nozzle/Tip Fabric Roll Cleaning Module | |

| Nozzle Vacuum Cleaning Module | |

| Industrial Barcode/QR Code Recognition System | |

| FFU | |

| Front Safety Light Curtain | |

| Non-contact Product Preheating Module | |

| Air Tank Booster Pump/Electric Proportional Valve (For High-Precision Dispensing) | |

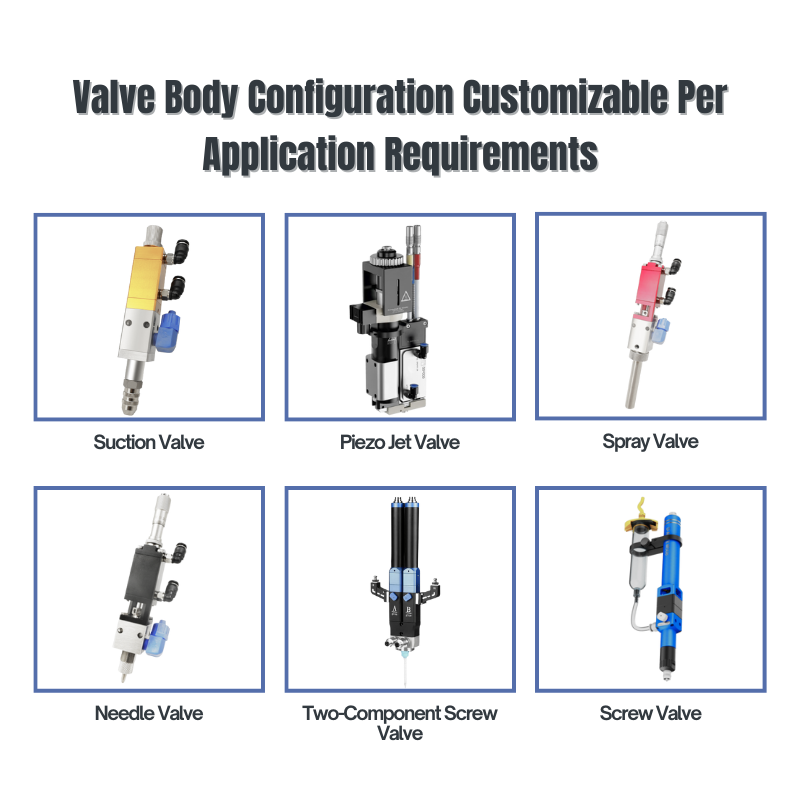

| Single Valve (Pneumatic/Piezo Jet Valve, Suction/Needle Valve, Single/Dual-Component Screw Valve, 30/50CC Syringe, etc.) | |

| Staggered Dual Valve (Non-synchronous Operation for Two Different Adhesives in One Machine) | |

| Synchronized Multi-Valve (2+ Valves Simultaneously Dispensing Same Adhesive with Uniform Spacing) | |

| Valve Tilting-Rotation Dispensing | Fixed-angle tilt with 360° circular dispensing

Auto-tilt/vertical switching for side-surface dispensing |

Please let us know !

What is the product being dispensed?

What type of adhesive is required?

What are the dispensing patterns and paths?

What are the accuracy requirements for dispensing?

Write your message here and send it to us