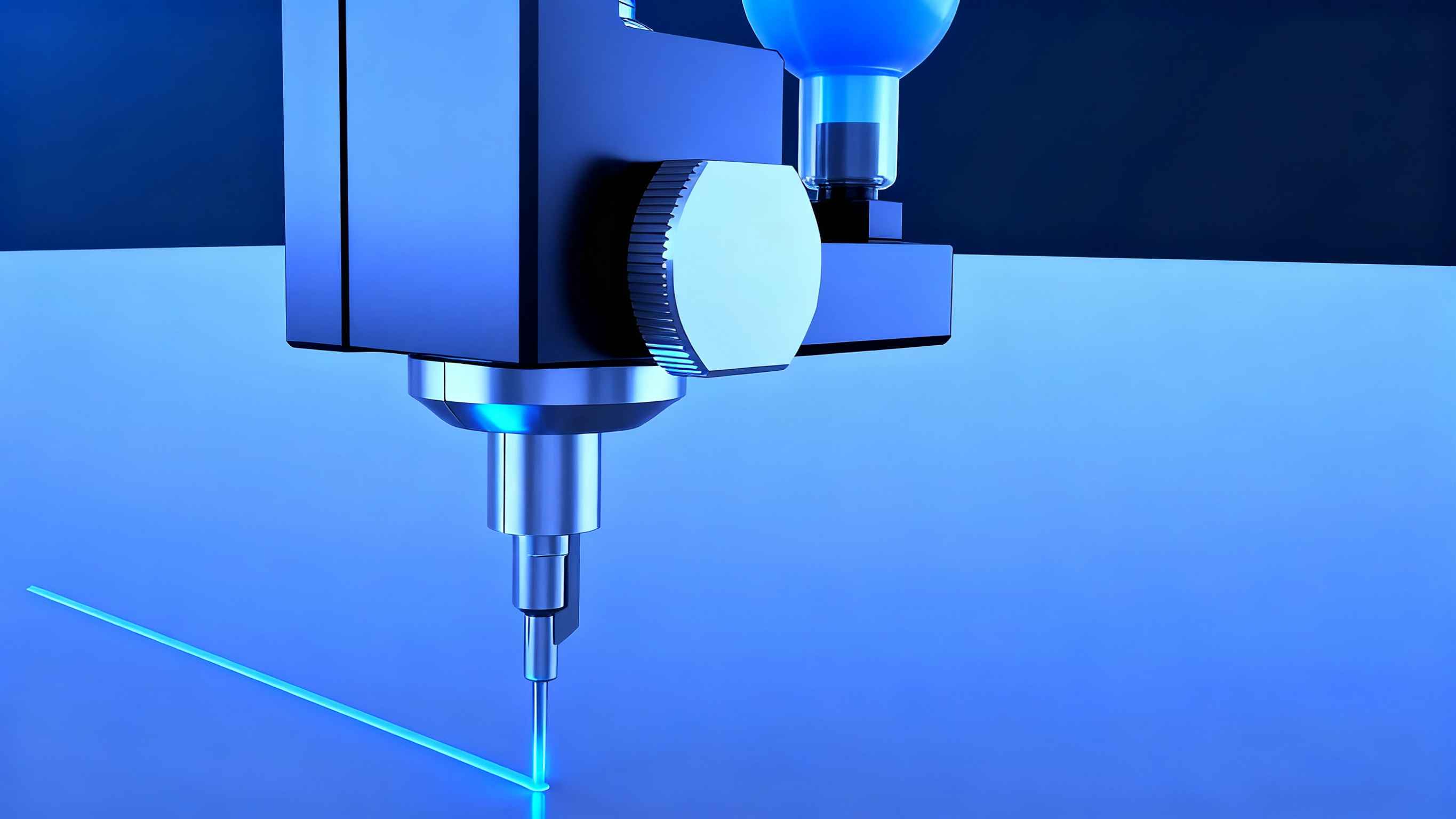

In modern manufacturing, dispensing machines serve as critical equipment and are widely used in electronics,

automotive,medical devices, and other fields. They not only enhance production efficiency and reduce labor

and manufacturing costs but also ensure consistent product quality. This article will elaborate on the pivotal

role of dispensing machines in modern manufacturing, exploring their advantages, application areas, and

future development trends.

Dispensing machines are widely used in various industries, with particularly prominent roles in fields such as

electronics, automotive, medical devices, optoelectronics, and solar energy.

Electronics Industry:

In electronics manufacturing, dispensing machines are widely used in chip encapsulation, PCB coating, and

component bonding. High-precision dispensing not only enhances product reliability but also effectively

reduces production costs.

Automotive Industry:

In automotive manufacturing, dispensing machines are applied in processes such as headlight sealing, body

bonding, and interior fastening. The efficiency and accuracy of dispensing ensure secure connections and

sealing of auto parts, improving vehicle safety and durability.

Medical Devices:

In medical device production, dispensing machines are used for bonding and sealing devices such as syringes,

catheters, and sensors. Precise control ensures high quality and reliability of medical products, meeting the

stringent safety requirements of the healthcare industry.

Optoelectronics & Solar Energy Industries:

Dispensing robots are also widely used in LED packaging and solar cell manufacturing, improving soldering

quality and reducing process defects.

How is the efficiency of your current manual dispensing process or existing older equipment?

High-Precision Control: Dispensing robots offer extremely high accuracy, enabling micrometer-level control over the size,

position, and shape of adhesive dots. This is particularly critical in demanding applications such as semiconductor

manufacturing, electronic components, and optoelectronic display devices. Traditional manual dispensing often leads to

uneven or excessive adhesive application, resulting in inconsistent production quality. In contrast, dispensing robots

ensure precise and consistent adhesive application every time.

Automation and Repeatability: Dispensing robots can operate continuously 24/7, maintaining consistent production

quality even under prolonged high workloads. This eliminates human fatigue-related errors and ensures uniformity in

the quality of every product.

High Efficiency: Dispensing robots can perform tasks at high speeds, significantly increasing production rates and shortening

cycle times compared to manual operations. They not only improve the efficiency of individual workstations but can also

integrate with other automated equipment (such as material handling robots and inspection robots) to form a fully automated

production line, further boosting overall productivity.

Reduced Labor Hours and Costs: Traditional manual dispensing requires extensive human involvement for repetitive tasks,

while dispensing robots operate continuously, reducing labor costs and minimizing human errors. In the long run, businesses

can achieve greater economic benefits by lowering labor expenses.

Adaptability to Various Adhesives and Materials: Dispensing robots are capable of handling a wide range of adhesives,including

UV curable adhesives, conductive adhesives, sealants, and structural adhesives. They are widely used across industries such as

electronics, automotive, medical, and solar energy. Their precision and versatility allow for flexible production adjustments to

meet the requirements of diverse products.

Manufacturing of Complex Products: As product designs become increasingly intricate, traditional manual dispensing often

struggles to meet complex application demands, such as dispensing in confined areas, creating fine lines, or adhering to

curved surfaces. Dispensing robots can adapt to various complex product structures and process requirements, delivering

higher manufacturing accuracy.

Precise Adhesive Control: Dispensing robots can accurately control the amount of adhesive applied in each operation,

preventing over-dispensing or under-dispensing. Excessive adhesive not only wastes material but may also compromise

product structure and performance, while insufficient adhesive can lead to weak bonding and reduced product quality.

Reduced Adhesive Waste: In traditional manual dispensing, adhesive waste is often significant. In contrast, robotic

dispensing systems regulate adhesive flow based on programmed requirements, minimizing waste and lowering costs.

Enhanced Bonding and Soldering Quality: Particularly in the electronics industry, dispensing robots ensure

consistent quality in soldering and bonding points, improving overall product reliability. For encapsulation and bonding

of electronic components, precise dispensing is fundamental to guaranteeing performance and stability.

Elimination of Human Errors: Manual dispensing is prone to various errors, such as uneven application, operational mistakes,

and missed spots. These errors can compromise production quality and increase costs associated with rework and repairs.

Dispensing robots, however, execute predefined tasks with precision, effectively eliminating human-induced errors.

Improved Worker Safety: Some adhesives, such as UV-curable adhesives and hot melt adhesives, may be toxic or emit irritating

odors. Prolonged exposure to these materials during manual dispensing can adversely affect workers' health. By replacing

manual operations, dispensing robots minimize workers' contact with hazardous materials, thereby enhancing overall safety in

the production environment.

Data Collection and Analysis: Modern dispensing robots are typically equipped with sensors and data acquisition systems,

enabling real-time monitoring of key parameters during the dispensing process (such as adhesive volume, pressure, speed,

and position). This data assists production personnel in optimizing adjustments, improving production quality, and also

provides essential support for quality traceability and issue analysis.

How is the efficiency of your current manual dispensing process or existing older equipment?

Dispensing robots, with their advantages of high precision, efficiency, automation, flexibility, and intelligence,

have significantly enhanced the production capabilities and product quality of modern manufacturing.

Whether in improving production efficiency,reducing costs, optimizing quality control, increasing production

flexibility, minimizing human errors, or ensuring operational safety, dispensing robots have brought

revolutionary changes to the manufacturing industry. With the advancement of smart technologies, dispensing

robots will continue to play a pivotal role across numerous sectors, driving further innovation and

transformation in modern manufacturing.

How is the efficiency of your current manual dispensing process or existing older equipment?

Post time: Sep-15-2025