In today's increasingly automated and precise manufacturing environment, dispensing equipment, as a key process step, determines product quality and production efficiency.

How to Choose the Right Dispensing Equipment? The selection of a dispensing machine should be based on actual requirements, involving multiple factors such as the working environment, the material to be dispensed, dispensing accuracy, production efficiency, and more. Here are the key factors to consider when choosing a dispensing machine:

Viscosity: Different dispensing materials (such as resin, glue, paint, etc.) have varying viscosities. Materials with higher viscosity require high-pressure dispensing equipment, while those with lower viscosity can be handled by low-pressure dispensing machines.

Rheology: Some materials may require more precise control to prevent overflow or dripping.

Curing Speed: For materials like instant adhesive or UV glue, considerations must be made for curing conditions, such as exposure to light or other hardening processes.

Dispensing Volume Accuracy: If there are high precision requirements for each dispensing location or volume, choose dispensing machines with precise control systems, such as servo-controlled systems.

Repeatability: A high-quality dispensing machine should have high repeatability to ensure that each dispensing amount is consistent throughout the production process.

Automation Level: Automated dispensing machines generally improve production efficiency by reducing manual intervention. Semi-automatic or manual dispensing machines are more suitable for small batch production.

Working Speed: The speed and dispensing volume of the machine should match the other equipment and production pace of the production line.

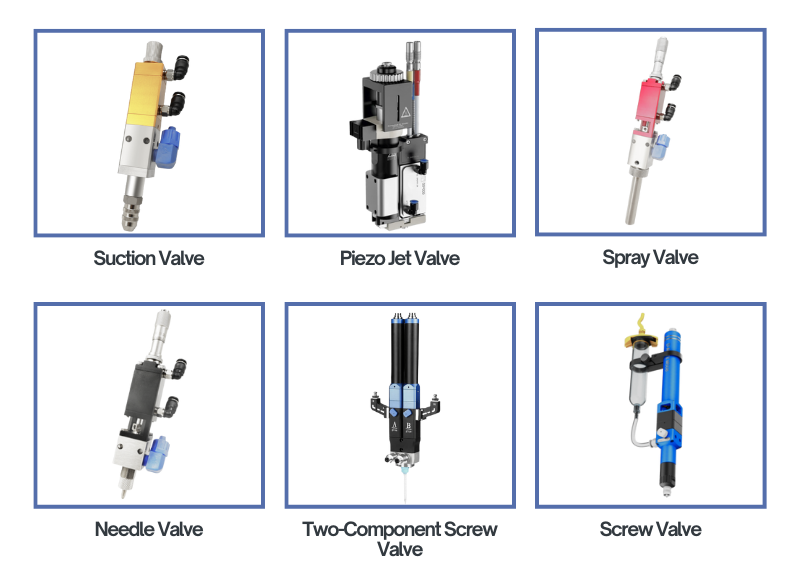

Jet Dispensing: Suitable for large-area or high-volume dispensing, commonly used in spraying, coating, and similar applications.

Needle-Valve Dispensing: Uses precise needle-valve control for dispensing, ideal for high-precision dispensing tasks.

Drop Dispensing: Suitable for precise, small-volume dispensing, typically used for delicate and detailed dispensing tasks.

Rotary Dispensing Head: Suitable for more complex dispensing processes.

Temperature and Humidity: Some dispensing machines perform better under specific temperature and humidity conditions. For example, UV dispensing requires a well-lit environment.

Dust and Corrosion Resistance: For dispensing machines used in harsh environments, it’s essential to choose equipment with dust-proof and corrosion-resistant features.

Vision System: Some dispensing machines are equipped with vision systems to identify the position of the target object, helping to improve dispensing accuracy.

Temperature Control System: For materials that require temperature control, choosing a dispensing machine with a temperature control function ensures consistent dispensing quality.

Foreign Object Detection: Some high-end dispensing machines can detect whether the dispensing amount is sufficient, helping to prevent under-dispensing.

Common Types of Dispensing Machines:

Desktop Dispensing Machine: Suitable for small-scale production and laboratory use, typically operated manually.

Automatic Dispensing Machine: Ideal for large-scale production, offering high production efficiency and consistency.

Precision Dispensing Machine: Designed for precise dispensing needs, such as soldering and packaging of electronic components.

Which type of dispensing machine are you looking for?

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment. Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

Post time: Sep-11-2025