Application in Semiconductor Industry

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment. Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

Bonding machines enable micro-interconnects with wire diameters, ensuring signal integrity; formic acid vacuum soldering forms reliable joints under oxygen content <10ppm, preventing oxidation failure in high-density packaging; AOI intercepts micron-level defects. This synergy ensures >99.95% advanced packaging yield, meeting the extreme testing demands of 5G/AI chips.

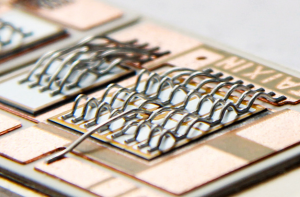

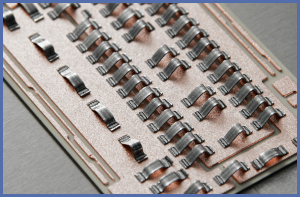

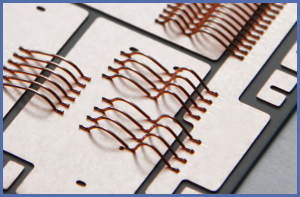

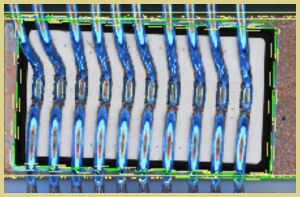

Ultrasonic Wire Bonder

Capable of bonding 100 μm–500 μm aluminum wire, 200 μm–500 μm copper wire, aluminum ribbons up to 2000 μm wide and 300 μm thick, as well as copper ribbons.

Travel range: 300 mm × 300 mm, 300 mm × 800 mm (customizable), with repeatability < ±3 μm

Travel range: 100 mm × 100 mm, with repeatability < ±3 μm

What is Wire Bonding Technology ?

Wire bonding is a microelectronic interconnection technique used to connect semiconductor devices to their packaging or substrates. As one of the most critical technologies in the semiconductor industry, it enables chip interfacing with external circuits in electronic devices.

Bonding Wire Materials

1. Aluminum (Al)

Superior electrical conductivity vs. gold, cost-effective

2. Copper (Cu)

25% higher electrical/thermal conductivity than Au

3. Gold (Au)

Optimal conductivity, corrosion resistance, and bonding reliability

4. Silver (Ag)

Highest conductivity among metals

Aluminum Wire

Aluminum Ribbon

Copper Wire

Copper Ribbon

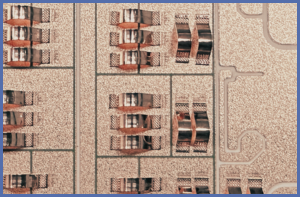

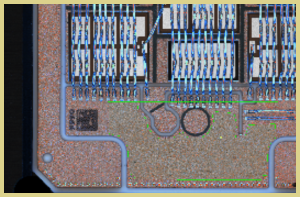

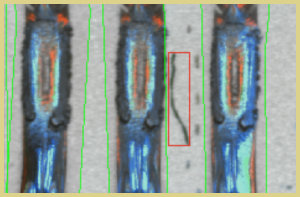

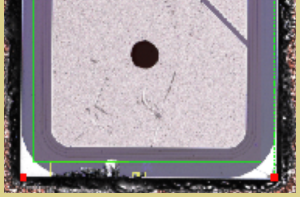

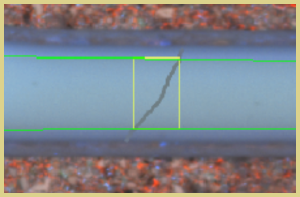

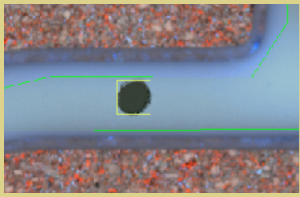

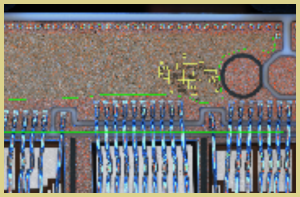

Semiconductor Die Bonding & Wire Bonding AOI

Uses a 25-megapixel industrial camera to detect die attach and wire bonding defects on products such as ICs, IGBTs, MOSFETs, and lead frames, achieving a defect detection rate greater than 99.9%.

Inspection Cases

Capable of inspecting chip height and flatness, chip offset, tilt, and chipping; solder ball non-adhesion and solder joint detachment; wire bonding defects including excessive or insufficient loop height, loop collapse, broken wires, missing wires, wire contact, wire bending, loop crossing, and excessive tail length; insufficient adhesive; and metal splatter.

Solder Ball/ Residue

Chip Scratch

Chip Placement, Dimension, Tilt Meas

Chip Contamination/Foreign Material

Chip Chipping

Ceramic Trench Cracks

Ceramic Trench Contamination

AMB Oxidation

In-Line Formic Acid Reflow Oven

1. Maximum temperature ≥ 450°C,minimum vacuum level < 5 Pa

2. Supports formic acid and nitrogen process environments

3. Single-point void rate ≦ 1%,overall void rate ≦ 2%

4. Water cooling + nitrogen cooling, equipped with a water-cooling system and contact cooling

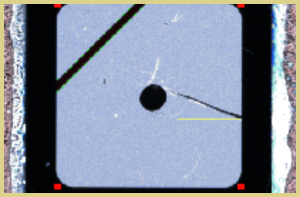

IGBT Power Semiconductor

Excessive voiding rates in IGBT soldering can trigger chain-reaction failures including thermal runaway, mechanical cracking, and electrical performance degradation. Reducing void rates to ≤1% substantially enhances device reliability and energy efficiency.

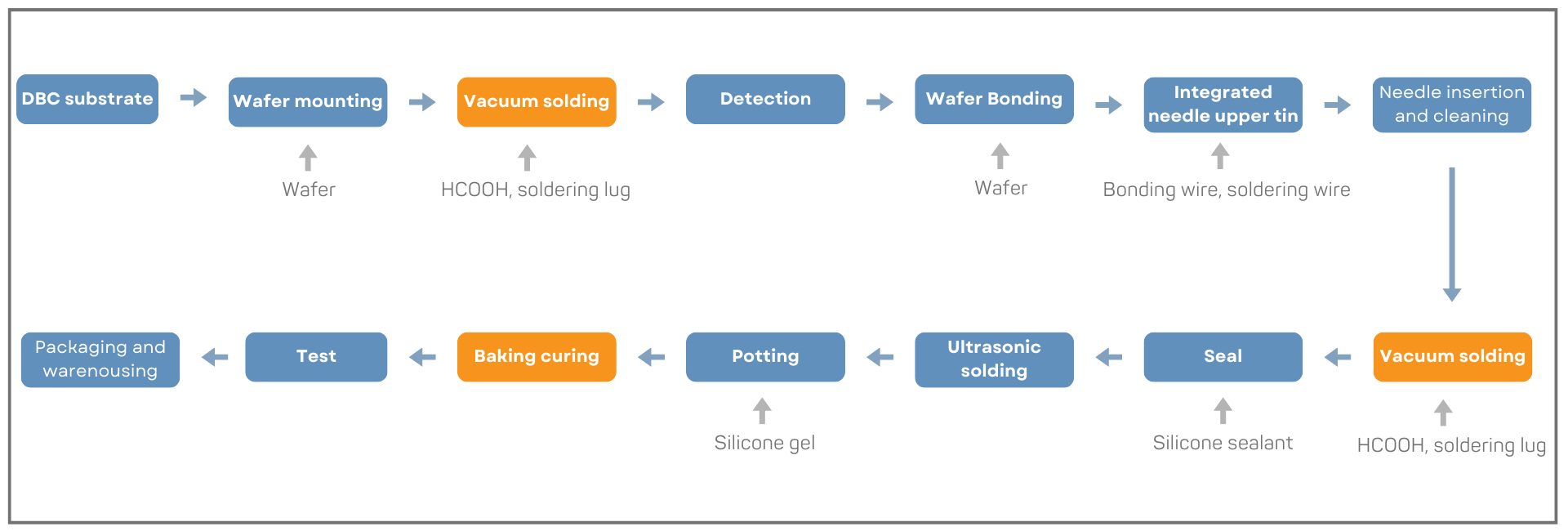

IGBT Production process flowchart