Chips? MEMS devices? LEDs? Or something else?

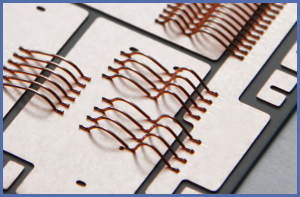

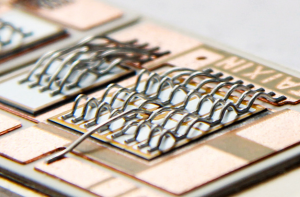

Aluminum Copper Wire Bonder Ultrasonic Wire Bonding Machine for High Power IGBT Battery LED PCBA

Bonding Wire Materials

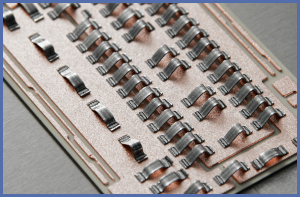

Heavy Wire Bonder is specifically designed for large-diameter wire bonding in IGBTs, intelligent power modules, and hybrid assemblies, delivering a stable and reliable professional solution.

What do you need to bond?

| X-Axis | 300 mm / Customizable Stroke (Optional) |

| Y-Axis | 300 mm / 800 mm, Customizable Stroke (Optional) |

| Z-Axis | Standard 50 mm, Optional 50‒100 mm |

| R-Axis | AC Servo Motor with Absolute Encoder (±220°), Resolution: 0.0035° |

| Height (Excluding Signal Light) | 1815 mm |

| Weight | 1400 kg |

| Working Height | SEMI MA850‒1050 mm Standard |

| Power Supply | 220V |

| Power Consumption | 1kW |

| Compressed Air Requirement | 0.5‒0.7 MPa (Clean, Dry Air) |

| Dimensions (L × W × H) | 750*1200*1850 mm |

| Image recognition | |

| Image Size | Traditional Image Recognition |

| Recognition Time | Each Recognition Cycle ≤2 ms |

| Alignment Correction | FlexSearch; Single-Point Recognition (Including Phase Angle), Dual-Point Recognition |

| Camera | Phase Angle Correction: ±5% |

| Resolution | Moving CCD Camera with Micron-Level Pixel Accuracy |

| Image Size | 2‒30 μm/Pixel (Adjustable via Optical Components) |

| Automatic tooling mode | |

| Pin-Type Stepper Transmission | Belt-Driven Stepper Transmission |

| Packaging Form | Flat Substrates (e.g., Ceramic Substrates, PCBs, or Workpiece Trays) |

| Automatic Conveyor Line | Customizable Automated Handling (AGV Mode Available) |

| Tandard Effective Welding Stroke | 300*300,300*800(mm) |

| Customizable Stroke | Expandable Travel Range (e.g., for Automotive Battery Packs) |

| Machine specifications | |

| X-Y Axis | Linear Encoder Resolution <0.1 μm |

| R Axis | ±220° AC Servo Motor with Absolute Encoder (Resolution: 0.0035°) |

| Z Axis | Optional 60 mm (2.36") Stroke with AC Servo Motor (Resolution: 0.5 μm) |

| Positioning Accuracy | <±5 μm @3σ (Includes Image/Wire/Bonder/Application) |

| Repeatability on Product | <±3 μm @3σ (Includes Image/Wire/Bonder/Application) |

| Display | 21" Flat Display |

| Microscope | Stereo Zoom Microscope with Adjustable Lighting |

| Connection | SMEMA、USB、RJ45、Digital 1/0 |

| Operating System | Real-Time Unix?-Based Multitasking OS |

| Certification | SEMIS2、CE |

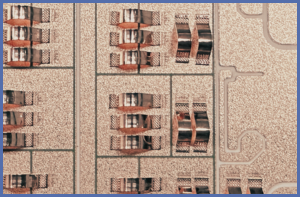

New energy power batteries, PV inverters, Frequency converters, Automotive electronics, Energy storage systems, IGBT modules,BMS (Battery Management System) safety control boards.

1.Fast System Switching - Seamless integration of heavy wire and ribbon bonding in a single platform.

2.Patented Process Control - Real-time parameter adjustments for varying material surfaces , ensuring repeatable weld quality.

3.Industry 4.0/OT Integration - Full process transparency through seamless smart factory compliance.

4.Multi-Frequency Ultrasonics - Selectable frequencies for optimal material matching and process stability.

5.Single-Source Automation - Unified process technology & automation from a single supplier.

Ready to learn more? Contact us today for a free quote!

Write your message here and send it to us