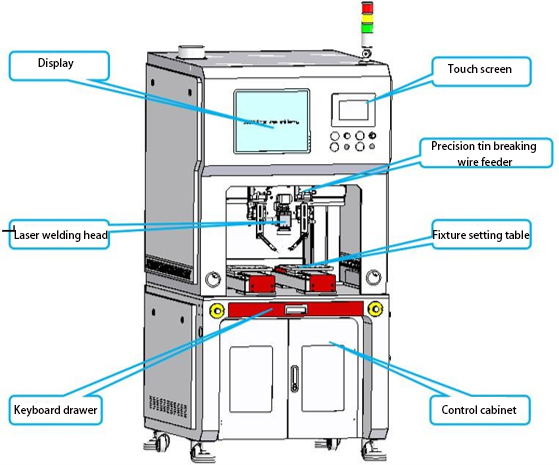

Vertical Tin Wire Laser Soldering Machine

Device Parameter

| Model | GR-F-LS5442C1 |

| Core Components | PLC, Engine, Motor |

| Voltage | 220V |

| Current | 10A |

| Weight | 400KG |

| Dimensions | 920mm×1020mm×1800mm |

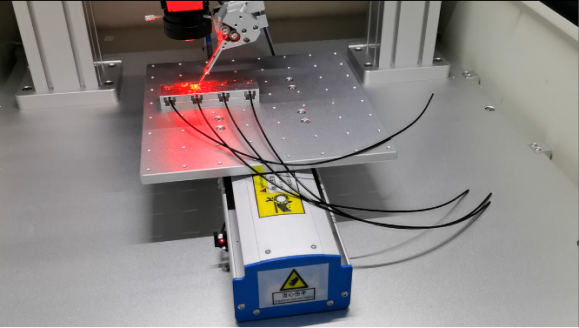

| Usage | wire soldering |

| Number of spindles | X, Y1, Y2, Z |

| Key Selling Points | Long Service Life |

| Power supply | AC220V 10A 50-60HZ |

| Platform itinerary | X=500, Y=400, Z=200mm |

| Processing range | 350*350mm |

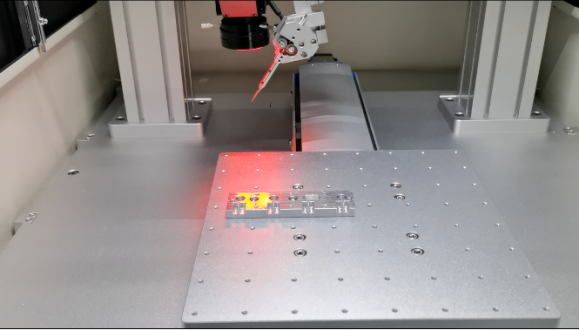

| Weld type | Laser tin wire |

| Laser type | Blue light semiconductor laser |

| Laser wavelength | 445nm |

| Maximum laser output power | 40W |

| Fiber core diameter | 400um |

| The power of the whole machine | 2.0KW |

| ooling mode | Air cooling |

Device features

1. High precision: the light spot can reach the micron level, and the processing time can be controlled by the program, making

the accuracy much higher than the traditional soldering process.

2. Non-contact processing: the soldering process can be completed without direct surface contact, so there is no stress caused by contact welding.

3. Small working space requirements: a small laser beam replaces the soldering iron tip, and precision processing is also

performed when there are other interferences on the surface of the workpiece.

4. Small working area: local heating, the heat-affected zone is small.

5. The working process is safe: there is no electrostatic threat during the processing.

6. The working process is clean and economical: laser processing consumables, no waste is generated during the processing.

7. simple operation and maintenance: laser soldering operation is simple, laser head maintenance convenience.

8. Service life: The life of the laser can be used for at least 10,000 hours, with long life and stable performance.

Application range

1. Wire, battery connector plug;

2. Soft and hard board;

3. Car lights, LED lights;

4. USB connector, capacitor resistor plug-in;